- sales@directionplus.com.au

- Brisbane, QLD, Australia

PRODUCT SEARCH

Product Search

Interest free for up to 6 months with learn more

Showing 9–16 of 259 results

-

New Products

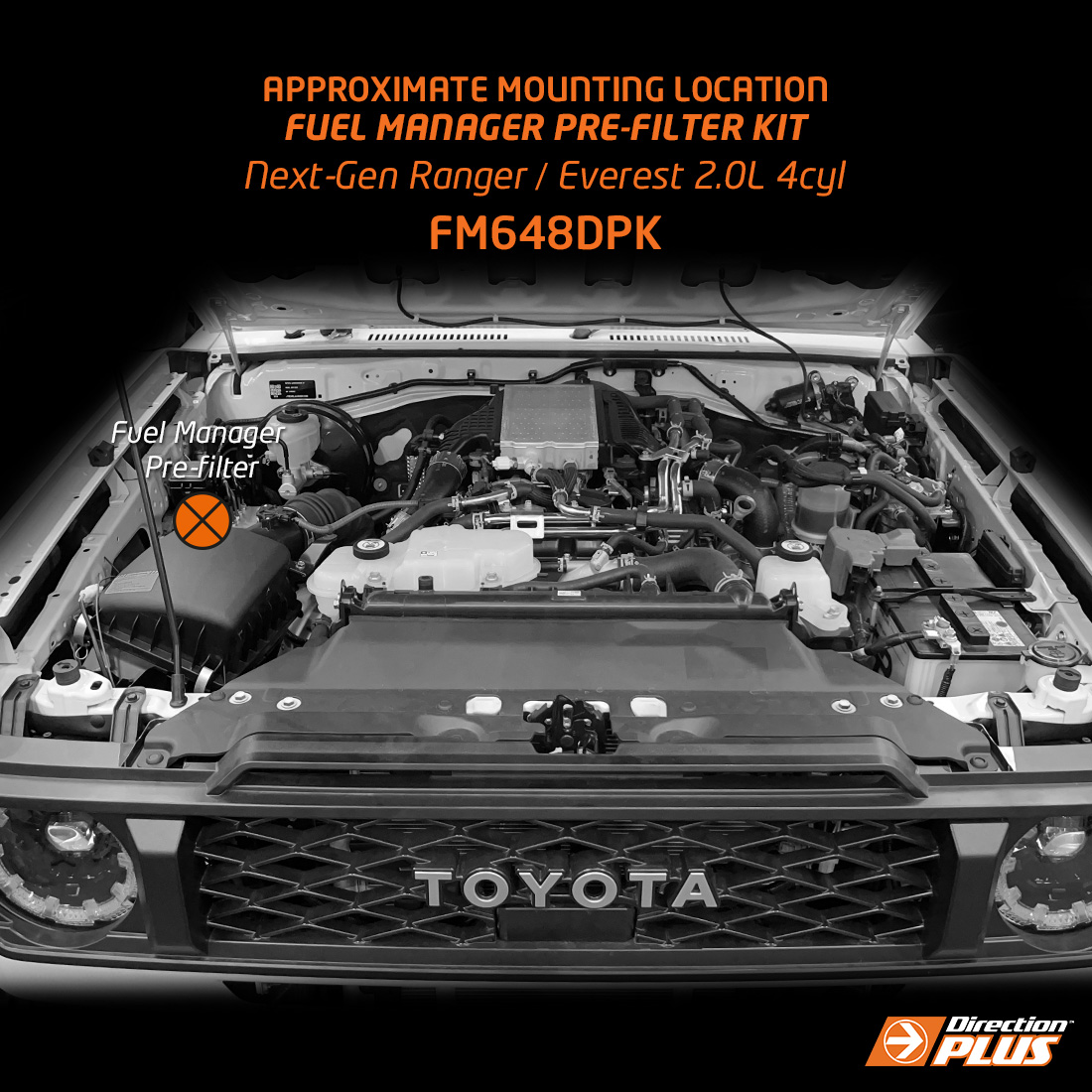

Fuel Manager Pre-Filter Kit LAND CRUISER 70 SERIES (FM648DPK)

Direction Plus™ Fuel Manager Pre-Filter Kit FM648DPK suits Toyota Land Cruiser 70 Series models, protecting its engine against costly injector failure.

This kit fits:

- Toyota Land Cruiser 70 Series 1GD-FTV (2.8L 4cyl) 2023 – On

PROTECT YOUR ENGINE

It’s easy to think that fuel contamination is something that happens “in the bush” but this is simply not true!

Did you know that 72% of all diesel fuel injection system failures are caused by water and fuel lubricity problems?

Direction Plus™ Fuel Manager Pre-Filter Kits protect late model common rail diesel engines against costly injector failure.

HOW IT WORKS

Installing a Direction Plus™ Fuel Manager Pre-filter kit between the fuel tank and the O.E.M fuel filter, the Fuel Manager will remove the majority of water and particle contamination. This leaves the O.E.M fuel filter to do the final and finer filtration. This ensures you are maximising the protection of your diesel fuel system.

For the ultimate front line defence against water and particle contamination, investing in a DirectionPlus™ Fuel Manager Pre-Filter Kit will protect your investment 24 hours a day, 365 days a year.

BENEFITS OF A FUEL MANAGER PRE-FILTER KIT:

-

Reduce wear & tear and avoid repair costs that can exceed $10,000

-

95% water separation and superior particle removal

-

Ability to separate emulsified water from ULSD

-

Clear water drainage bowl to easily identify removed water

-

Keeps critical engine components clean

-

No filter bypass – contaminated fuel will not be sent to the fuel system even when the filter is blocked

Check fitment guide below to confirm suitability for your vehicle.

(0 reviews)$599.00 Add to cart -

Pre-Filter Kits

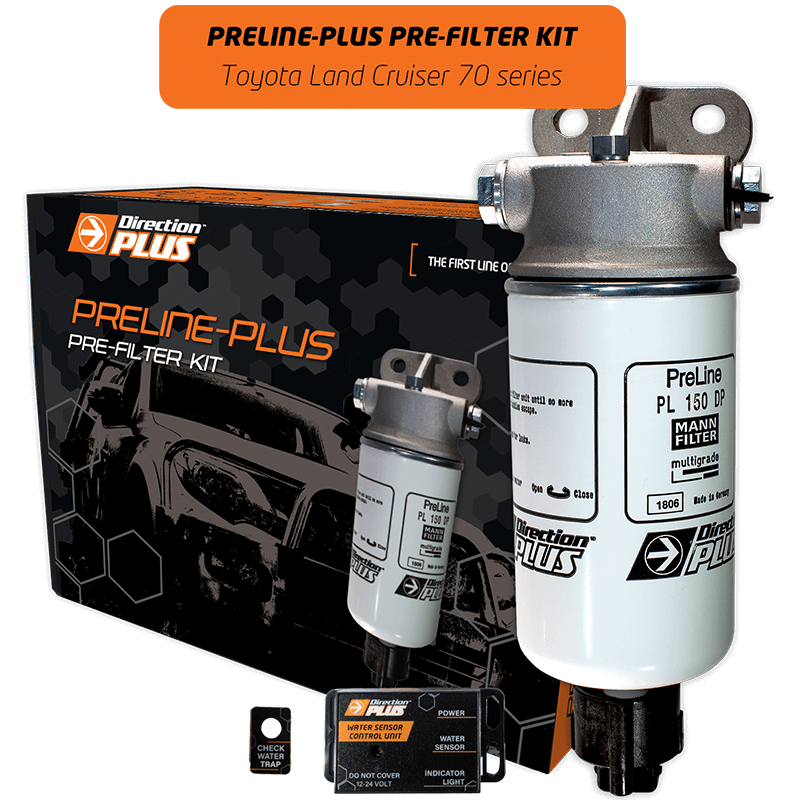

PreLine-Plus Pre-Filter Kit LAND CRUISER 70 (PL648DPK)

Direction-Plus™ PreLine-Plus PL648DPK is an innovative pre-filter system for diesel fuel which suits Toyota Landcruiser 70 series 1GD-FTV 2.8L 4cyl (2023 – On) models. Driver side mounting location.

This kit fits:

- Toyota Land Cruiser 70 Series 1GD-FTV (2.8L 4cyl) 2023 – On

PROTECT YOUR ENGINE

PreLine-Plus pre-filter system is designed specifically to cope with extreme weather conditions and poor fuel quality ensuring a high degree of water separation and particle pre-separation.

WATER SEPARATION EFFICIENCY

With a 100% water separation efficiency rating (based on 300um droplet size) and a long service life, meeting the specifications set by leading manufacturers of diesel fuel injection systems, this PreLine-Plus pre-filter kit will reliably protect your fuel system from corrosion, abrasion and the frequency of repairs reduced.

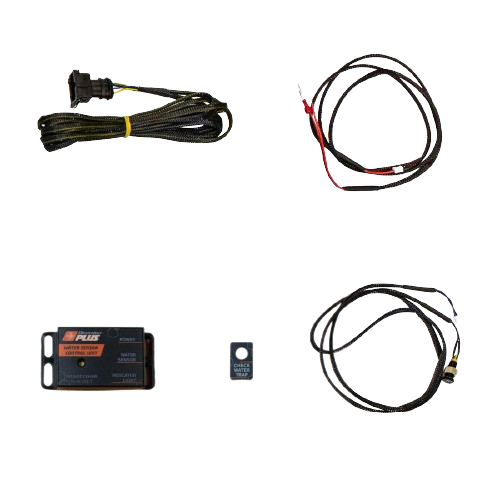

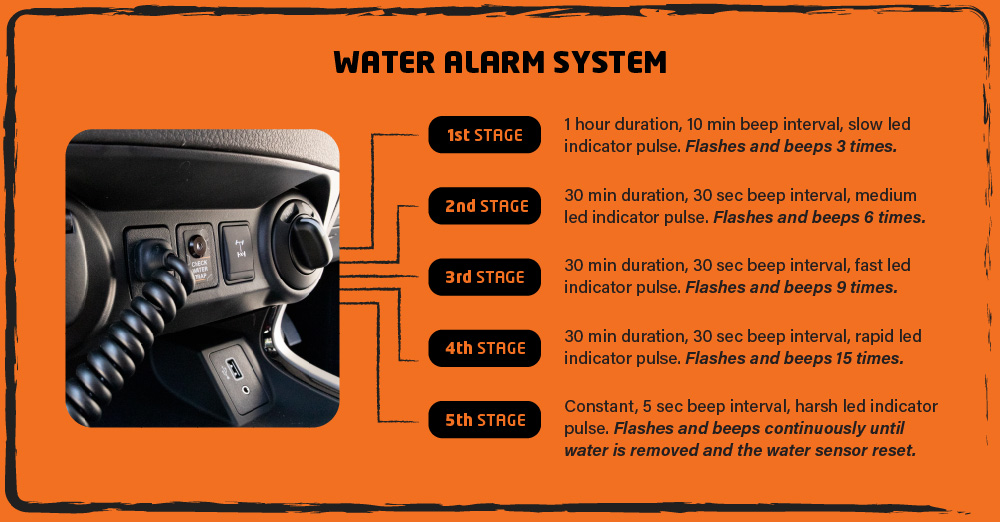

WATER ALERT SYSTEM

The PreLine-Plus kit includes an intuitive multi-stage water alert that separates it from other kits on the market. The alarm will notify the driver in the event that water is detected in the fuel which also eliminates the need to manually check for water.

BENEFITS OF FITTING A PRELINE-PLUS PRE-FILTER KIT:

-

Remote multi-stage water alert system (visual and audible)

-

100% water separation efficiency (based on 150μm droplet size)

-

98% particle separation (based on 30 micron particles)

-

Reliable protection from corrosion and abrasion

-

No need to visually check for water – included alarm

-

Simple spin on style filter

[yotuwp type=”videos” id=”PXuzmHKsWM0″ player=”width=550″]

Check fitment guide below to confirm suitability for your vehicle.

(0 reviews)$648.00 Add to cart -

New Products

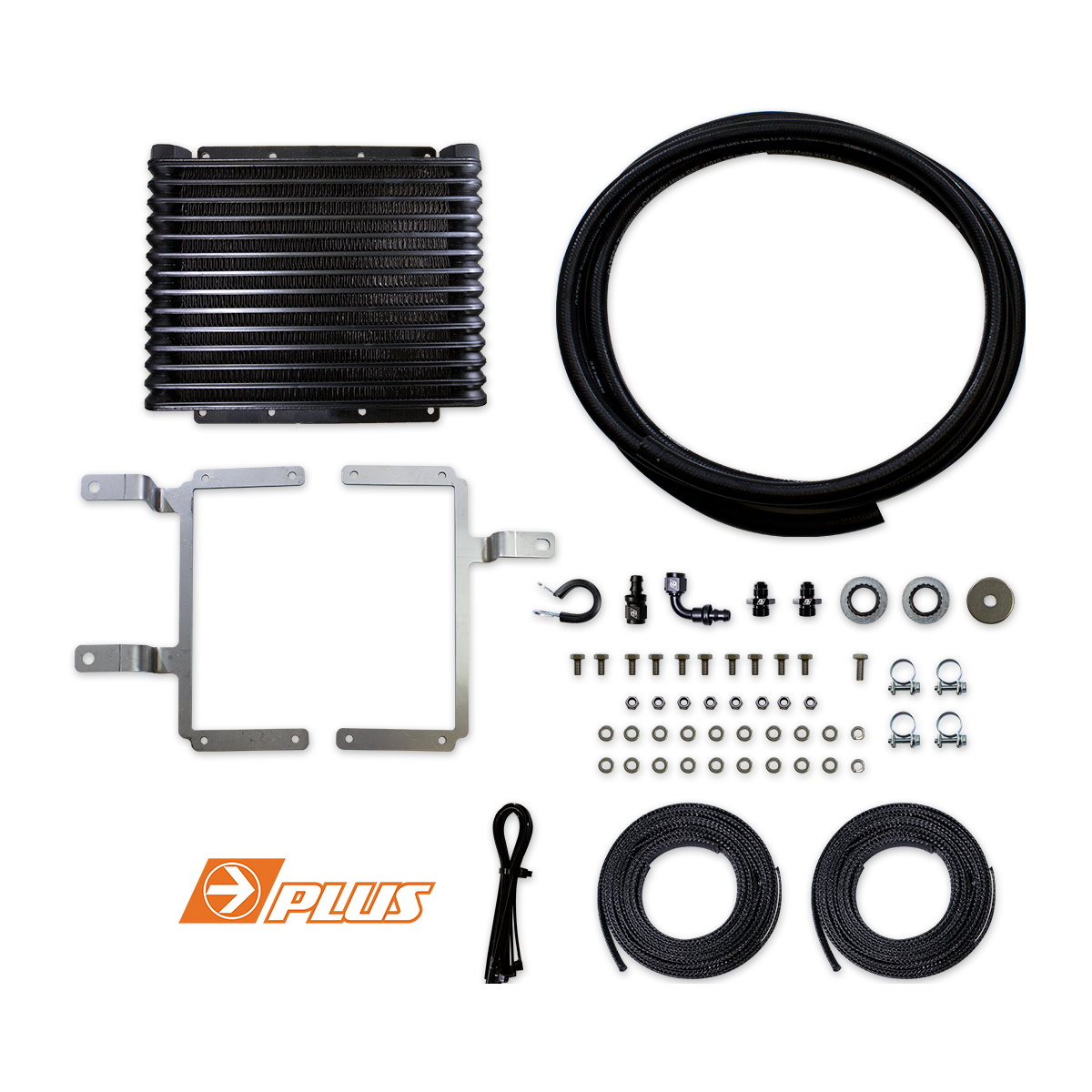

TransChill Arctic Black Transmission Cooler Kit ISUZU D-MAX & MU-X (TCB601DPK)

The NEW 32mm 14 row TransChill Transmission cooler kit TCB601DPK fits Isuzu D-Max and MU-X 4JJ1TCX (3.0L 4cyl) 2012 – 2020 models and is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The 32mm TransChill Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

New & Improved model

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

100% pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

Up to 50% more efficient (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler Kit can reduce the temperature of the ATF by as much as 33°C and assist maintaining acceptable operating temperatures. A reduction of just 11°C that can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

All mounting hardware included

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

[yotuwp type=”videos” id=”QyDP8KydZqA” player=”width=500″]

(0 reviews)$499.00 Add to cart -

-

New Products

TransChill Arctic Black Transmission Cooler Kit TOYOTA LAND CRUISER 300 SERIES (TCB635DPK)

The Transchill Arctic Black Transmission cooler kit TCB635DPK fits:

Toyota Landcruiser 300 Series F33A-FTV (3.3L 6cyl) 2022 – On

* Vehicles with standard bumper may require minor trimming of some plastic bumper supports.

This transmission cooler is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The 32mm TransChill Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

New & Improved model

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

100% pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

Up to 50% more efficient (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler can reduce the temperature of the ATF by as much as 33°C which can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

All mounting hardware included

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

[yotuwp type=”videos” id=”QyDP8KydZqA” player=”width=500″]

(0 reviews)$529.00 Add to cart -

-

New Products

TransChill Arctic Black Transmission Cooler Kit FORD NEXT GEN RANGER / EVEREST (TCB671DPK)

The TransChill Arctic Black Transmission cooler kit TCB671DPK fits:

- Ford Next Gen Ranger YN2S (2.0L 4cyl) 2022 – On

- Ford Next Gen Everest YN2S (2.0L 4cyl) 2022 – On

This Transmission Cooler is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The 32mm TransChill Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

New & Improved model

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

100% pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

Up to 50% more efficient (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler can reduce the temperature of the ATF by as much as 33°C which can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

All mounting hardware included

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

[yotuwp type=”videos” id=”QyDP8KydZqA” player=”width=500″]

(0 reviews)$699.00 Add to cart -

TransChill Transmission Oil Cooler Kits

TransChill Arctic Black Transmission Cooler Kit TOYOTA PRADO 150 & 155 Series (TCB620DPK)

The TransChill Arctic Black Transmission cooler kit TCB620DPK fits:

- Toyota Prado 150 Series 1KD-FTV (3.0L 4cyl)

- Toyota Prado 150 Series 1GD-FTV (2.8L 4cyl) 2009 – On models

- Toyota Prado 155 Series 1KD-FTV (3.0L 4cyl)

- Toyota Prado 155 Series 1GD-FTV (2.8L 4cyl) 2009 – On models

This product is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The TransChill Arctic Black Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

New & Improved model

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

100% pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

Up to 50% more efficient (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler can reduce the temperature of the ATF by as much as 33°C which can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

All mounting hardware included

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

[yotuwp type=”videos” id=”QyDP8KydZqA” player=”width=500″]

(0 reviews)$499.00 Add to cart -

TransChill Transmission Oil Cooler Kits

TransChill Arctic Black Transmission Cooler Kit NISSAN NAVARA NP300 (TCB630DPK)

The NEW & IMPROVED 32mm 14 row Arctic Black TransChill Transmission Oil Cooler Kit (TCB630DPK) suits the Nissan Navara NP300 YS23DTTi (2.3L 4cyl) 2015- On models and is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The 32mm TransChill Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

Pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

75% more performance than a comparable tube and fin design (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler Kit can reduce the temperature of the ATF by as much as 33°C and assist maintaining acceptable operating temperatures. A reduction of just 11°C that can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Australian Made vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

Locally designed and packed with all the mounting hardware required for a DIY installation

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

(0 reviews)$545.00 Add to cart -

-

TransChill Transmission Oil Cooler Kits

TransChill Arctic Black Transmission Cooler Kit for D-MAX & BT-50 (TCB645DPK)

The NEW 32mm 14 row TransChill Transmission cooler kit TCB645DPK fits Isuzu D-Max and Mazda BT-50 4JJ3-TCX (3.0L 4cyl) 2020 – On models and is designed specifically to reduce excessive transmission heat caused by towing, carrying loads and driving in sand, snow, off-road or hot conditions.

The 32mm TransChill Transmission cooler is an effective & economical way to keep the transmission at its optimum operating temperature. High efficiency turbulators in each tube direct the fluid for superior heat transfer. The unique 32mm plate & fin design allows for extreme cooling whilst the compact design is perfect for our vehicle specific mounting.

-

New & Improved model

-

32mm, 14 row fin & plate design allows for extreme cooling

-

Durable Black powder coat resists oxidisation

-

100% pressure tested at 150psi for quality assurance

-

Internal tubulation for efficient heat transfer

-

Up to 50% more efficient (*heat transfer rate – BTU/hr)

-

Pre-drilled mounting plates for easy installation

-

Inlet & Outlet size: M16 fittings

WHY DO YOU NEED ONE?

Due to the extreme heat generated in an automatic transmission, an auxiliary oil cooler is an economical and efficient way to help protect against costly transmission repairs.

Automatic Transmission Fluid (ATF) cools, lubricates and cleans internal transmission components. When transmission components exceed 93°C (200°F) the performance of ATF is seriously compromised.Subsequently the life span of the ATF, seals and internal components of the transmission are significantly reduced. Higher internal temperatures also increase the wear rate of the friction and clutch plates.

HOW IT WORKS

The Direction-Plus™ Transmission Cooler Kit can reduce the temperature of the ATF by as much as 33°C and assist maintaining acceptable operating temperatures. A reduction of just 11°C that can double the life expectancy of the transmission, ATF and all internal components.

AUTOMATIC TRANSCHILL CONTENTS:

-

-

Vehicle specific laser cut 4mm 5005-H34 aluminum mounting brackets

-

All mounting hardware included

-

ATF Hose (Meets or exceeds SAE J1019 requirements)

-

1x Davies Craig Black 32mm 14 row oil cooler

-

3yr Warranty *Conditions apply

-

Check fitment guide below to confirm suitability for your vehicle.

[yotuwp type=”videos” id=”QyDP8KydZqA” player=”width=500″]

(0 reviews)$599.00 Add to cart -

Quick links

Information

help & support

get in touch

- sales@directionplus.com.au

- Brisbane, QLD, Australia

- 1800 037 587

SUBSCRIBE TO NEWSLETTER

SUBSCRIBE TO NEWSLETTER

Copyright © 2023. Direction-Plus™

Follow us on social media